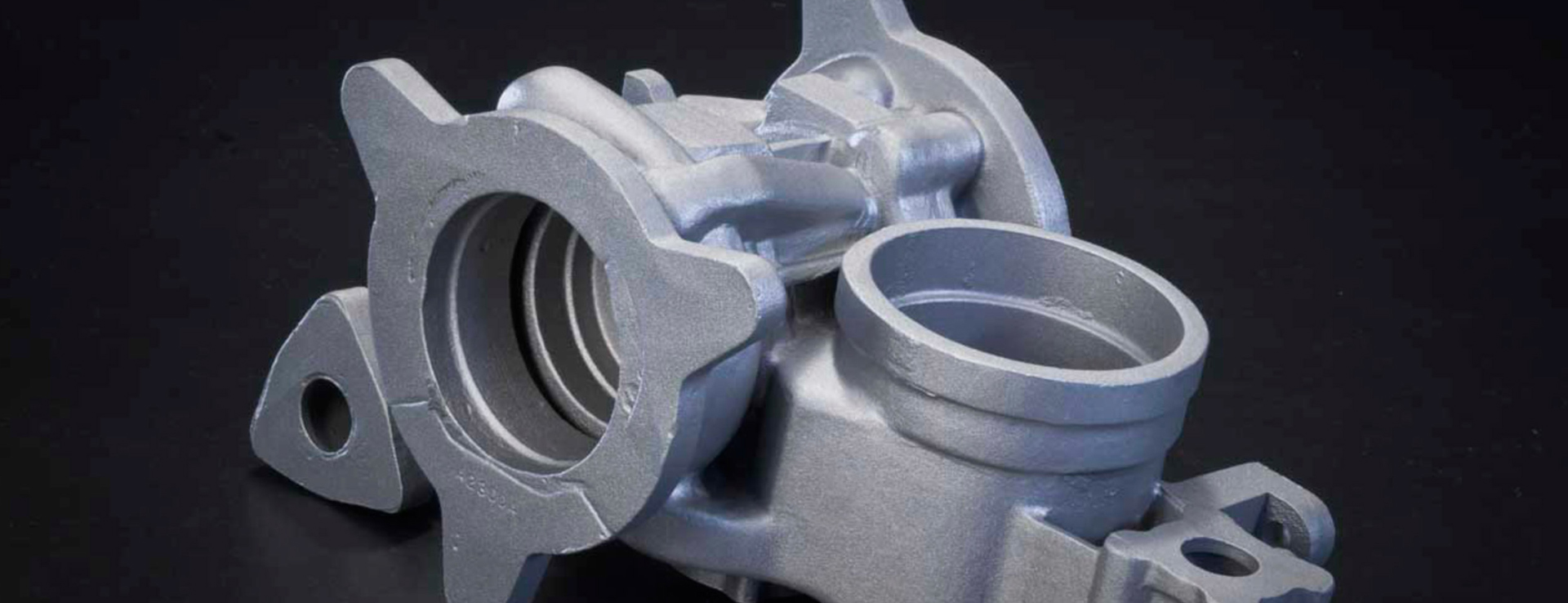

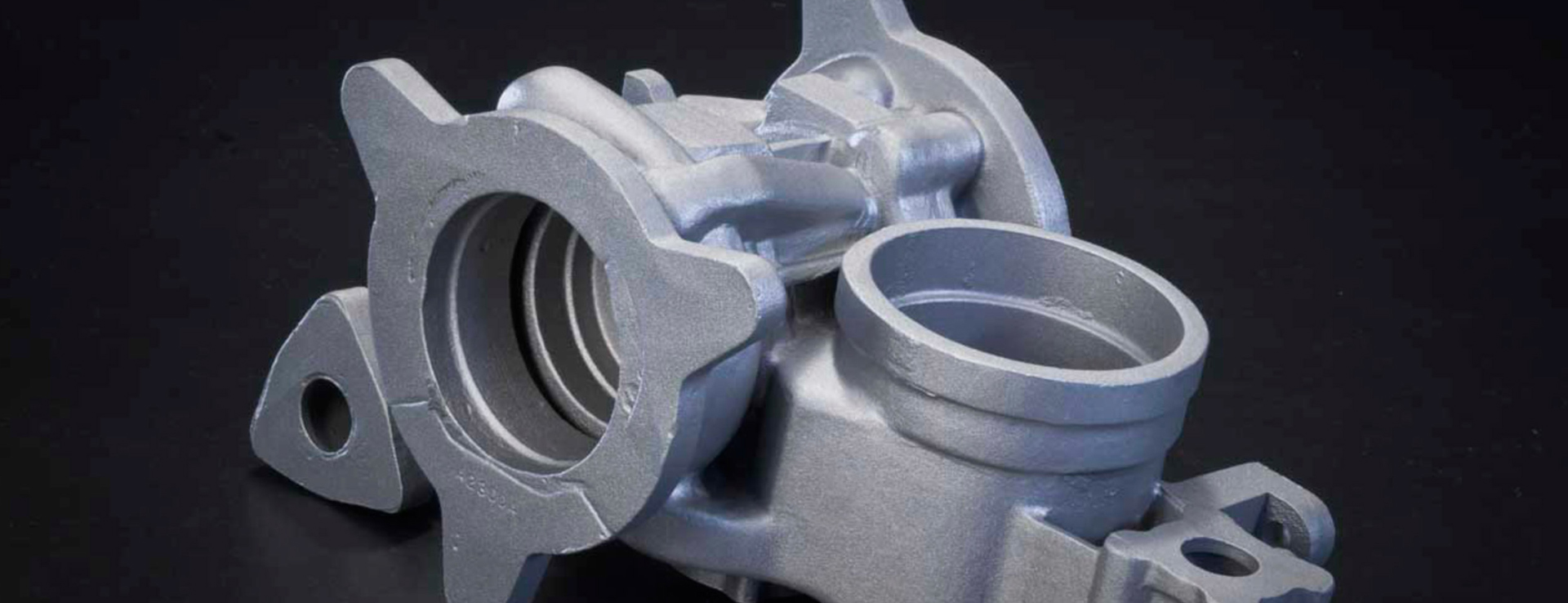

Aluminum Casting highly flexible form of

casting that allows for the usage of recyclable and permanent patterns.

Aluminum Casting is an ideal way of creating various aluminum products that

extensively suitably find applications in distinguished industries. These

castings are manufactured by utilizing the topmost quality aluminum material

with the implementation of molding methodologies. This range of aluminum

cast can be availed by wide clients in various sizes, shapes, dimensions and

specifications as per their application requirements. Moreover Aluminum is a

versatile material used for many applications, giving mechanical designers

significant advantages when creating lightweight parts that withstand high

temperatures. Aluminum die casting is often used in the automotive,

construction and electrical industry as a light and durable alternative to

other metals while retaining maximum stability in thin walls. It's an

exceptional thermal conductor for heat dissipation while maintaining

rigidity and resilience when used for EMI/RFI shielding in the telecom and

electronics industries. Because of its superior performance, aluminum die

casting provides several advantages over alternative processes and materials

including:

- Lightweight

- High dimensional stability

- Corrosion resistance

- Excellent mechanical

properties

- Superior EMI and RFI

shielding properties

- High thermal and

electrical conductivity

- High Strength-to-weight

ratio

- A variety of decorative

and protective finishes

- Made from 100% recycled

material and fully recyclable